Coffee Project Part IV - Django Roast App

Background

Some information were blacked out to protect the privacy of the company

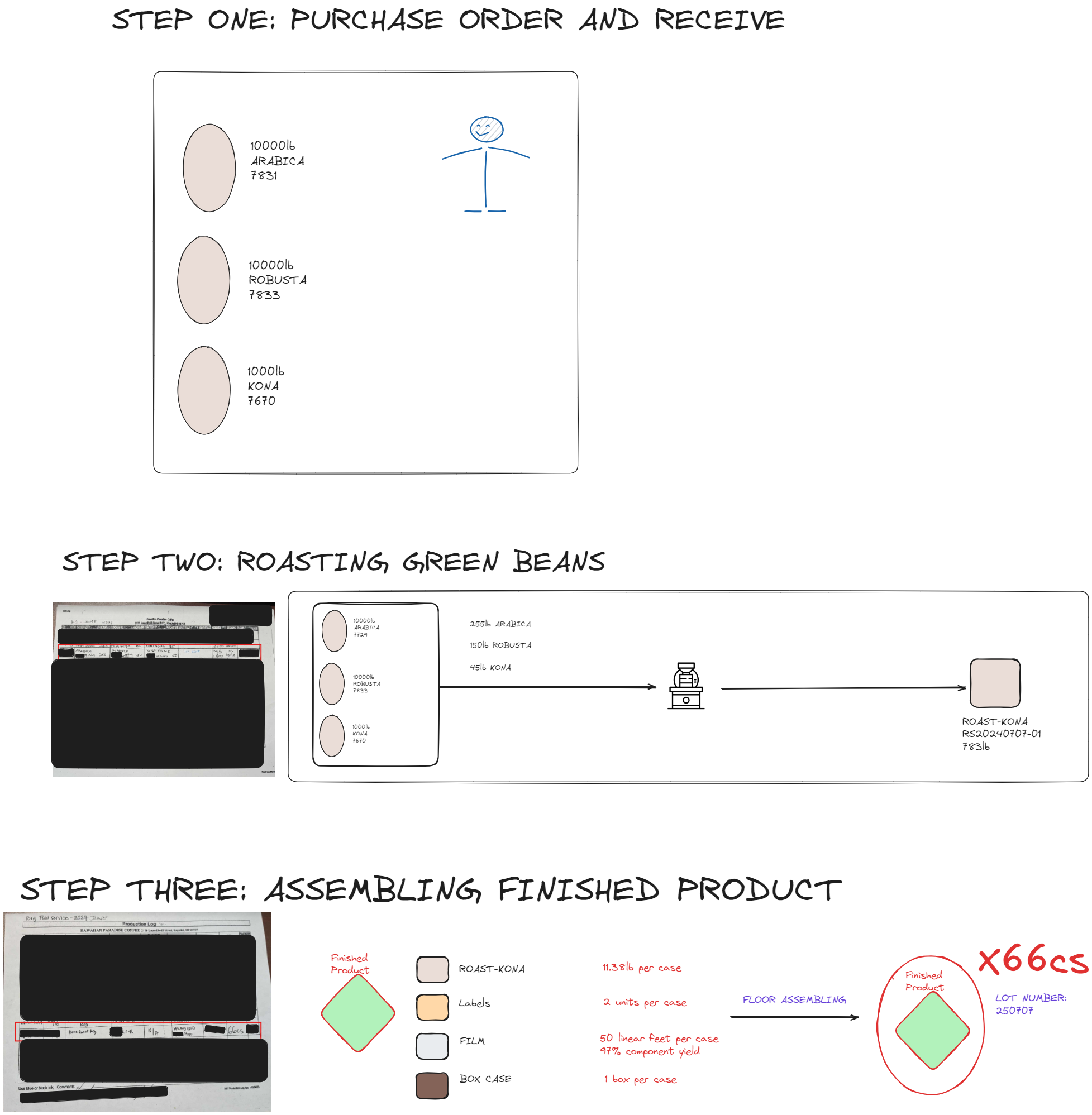

In Part I, it is established what is a Bill of Materials (BOMs) and a revision. In Part II, we got more granular and defined the components within a BOM and its' revision. Finally, in Part III, an Assembly Build will draw the components' quantities by the lots to positively increase a finished good inventory reflecting on the physical manufacturing process.

During this time, I was given the opportunity to work directly with the local coffee company to assist them with their technical aspects of operations - calculating the Cost of Goods (COGs) was the primary objective. Calculating the COGs is important as it allows the company to evaluate its' operation efficiency, pricing strategies, profitability, and understanding the companies' overall financial health.

When I hopped onboard, I notice inefficiencies with operations and their data flow. In particular, I noticed that their logs were paper-based and that their production data weren't being pushed into a database.

An example of the paper log is displayed below. You can see the green beans components and its' lots are roasted to produce the finished product listed on the right hand side.

Furthermore, when the Production produce stock inventory of a finished good, in order to add the supply into NetSuite my colleague had to do an Inventory Adjustment. The inventory adjustment transaction changes the quantity and value of an inventory item without entering a purchase order. Inventory adjustments are meant to account for clerical errors, changes in cost, thefts, or miscounts but not a true reflection on Production process like an Assembly Build does. The adjustment transactions do not take account of component cost so you are not capturing true data from production to utilize the benefits of Assembly Builds.

Once I realized this inefficiency, I used my prior experience with other development projects to write a web application (The Roast App) that allow production workers to input their data. From my web application, I pushed the data to NetSuite backend using their RESTlet feature. The process accounted for over 100+ recipes for finished products and ultimately closed the loop between Production, Accounting, and Sales of product and reduced inefficiencies in redundant data entries.

Case Study:

The diagram below show how the physical log and the process when it comes to receiving components and assembling the product (from roasting to packaging)

The video below showcase the Digital Form of the Roast App for Roasting (Step 2)

The video below showcase the Digital Form of the Roast App for Assembling Finished Product (Step 3):

Benefits of Capturing Production Data

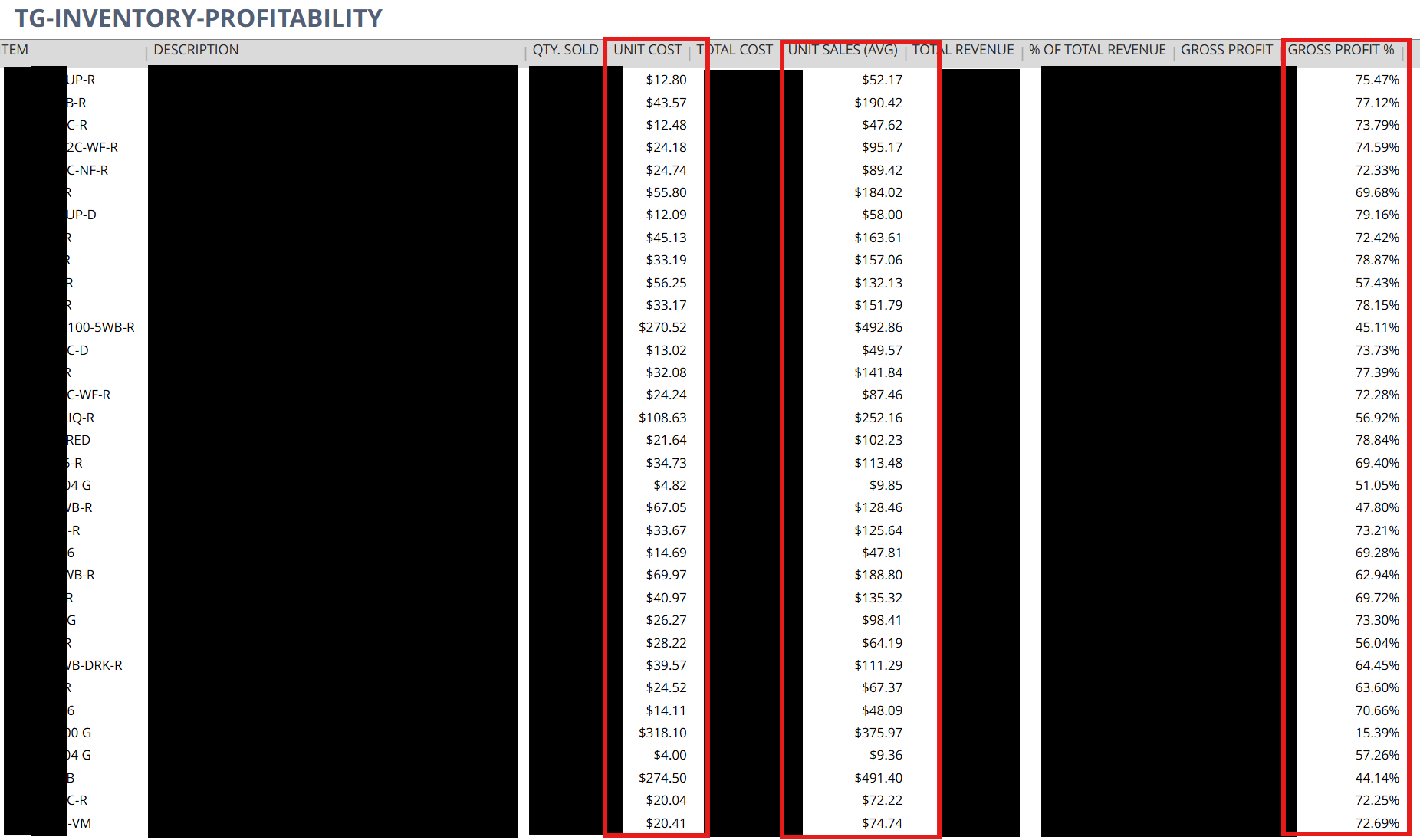

Understanding Profit Margin

With the roast app being in production, we were able to eliminate unnecessary Inventory Adjustments and allows Production to reflect their physical manufacturing process in NetSuite Database. That allows us to have a consistent flow of data, real-time stock replenishing (we do not have to wait for my colleague to do inventory adjustments), and true analysis of finished goods component cost.

I created a report in NetSuite to extrapolate the sales data and the manufacturing data (Unit Sales Price vs. Unit Costing Price) per item and get an accurate picture of the Gross Profit per item. The integrity of data allows us to make better business decision as to which item need a price increase or which item does not meet the standard of Gross Profit %.

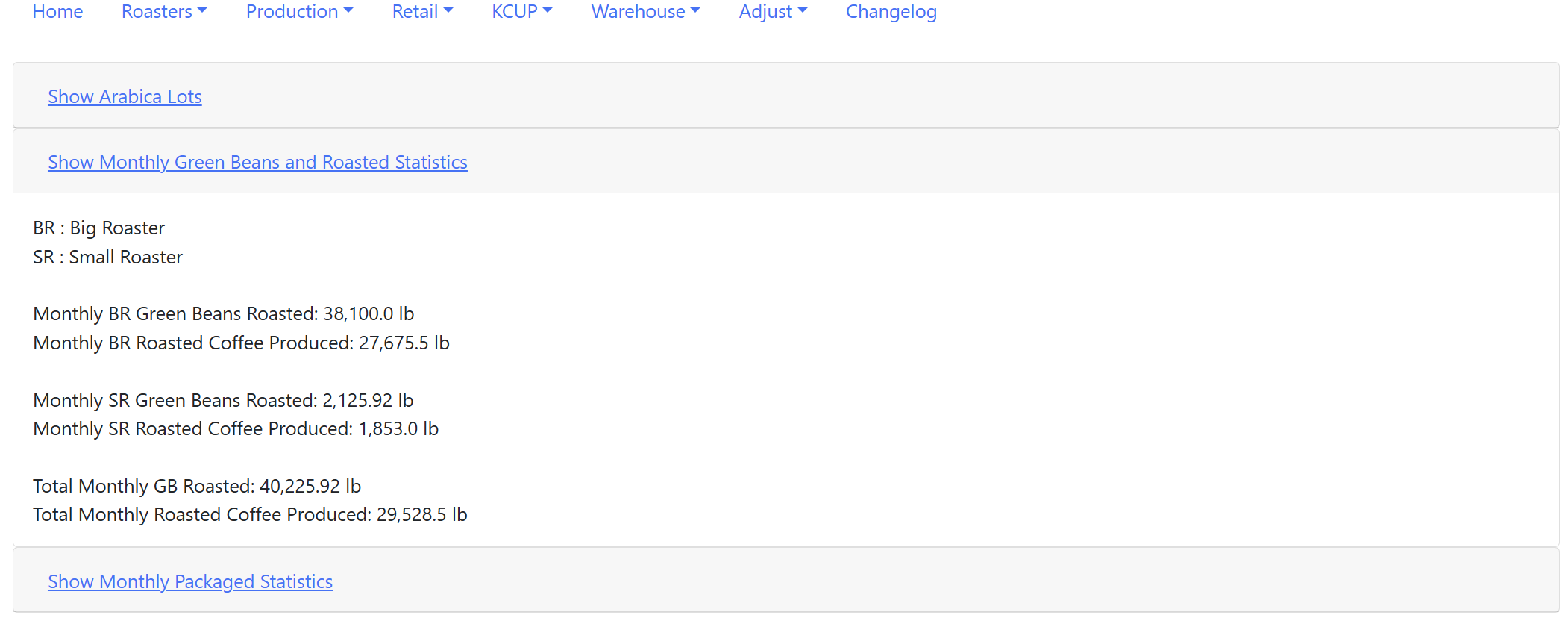

Understanding Manufacturing Efficiency

When the operators of the machine input their production data into the Roast App, I am able to capture and extrapolate those data. Unlike the paper logs, I can quickly calculate and analyze the flow of components material and the manufacturing process. For example, at any given point of time in the month, I am able to see the current quantity of beans that are being roasted and whether or not we meet the projected poundage to meet sales demand.

Special Thanks

I wanted to give special thanks to the resources below that helped me to create my Django Roast App and and integrated the Assembly Build feature between the Web application to NetSuite Database:

-

Mark Clifford on his article How to Automate Assembly Builds in NetSuite - this was helpful as NetSuite native API for Assembly Build documentation was not helpful in terms of Inventory Detail by the lots. The key was to use RESTlet to achieve the data push between your web application and NetSuite.

-

Robin Mitchell from Head in the Cloud for providing some really useful YouTube video tutorial on how to start your integration using Oauth1 or Oauth2 to NetSuite.

-

Tim Dietrich for his SuiteAPI which helped me understand the data model and logic that NetSuite uses for its' backend transaction.