Coffee Project Part III - Component Utilization via Assembly Build

Background

In Part I, it was defined what is a Bill of Material (BOM). In Part II, we moved onto to the components aspect of BOMs. In this portion, we will go over how NetSuite's Assembly Build uses the BOM and the components definition in the Revisions to utilize the stock inventory to assemble a finished product.

How to Build a Finished Good through Assembly Build

-

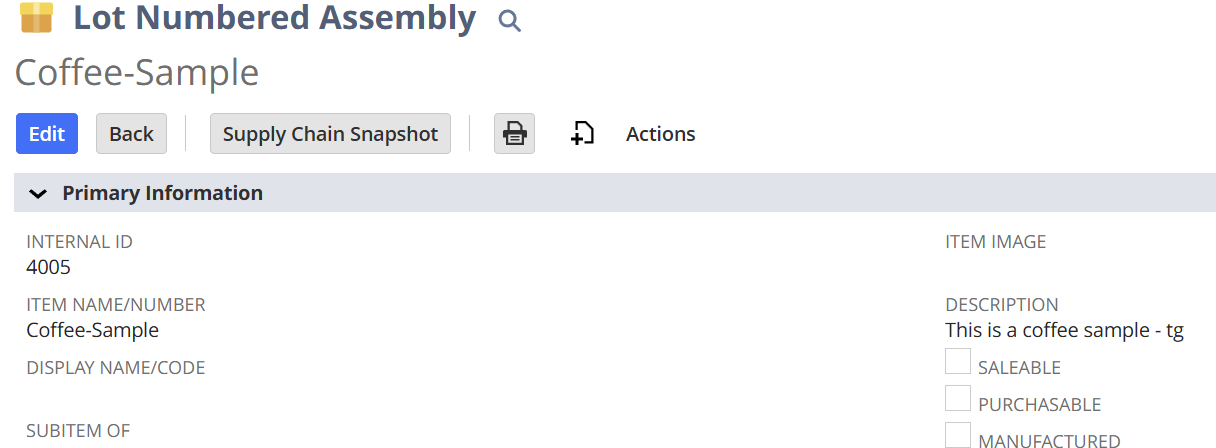

In this example, we will look at a test finished product with the Item SKU named "Coffee-Sample":

-

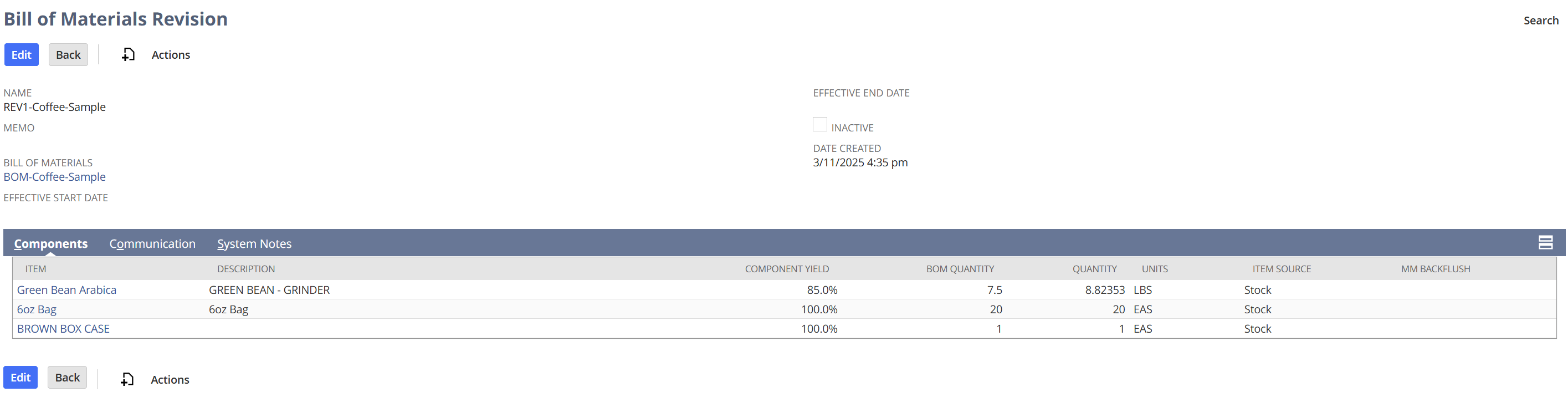

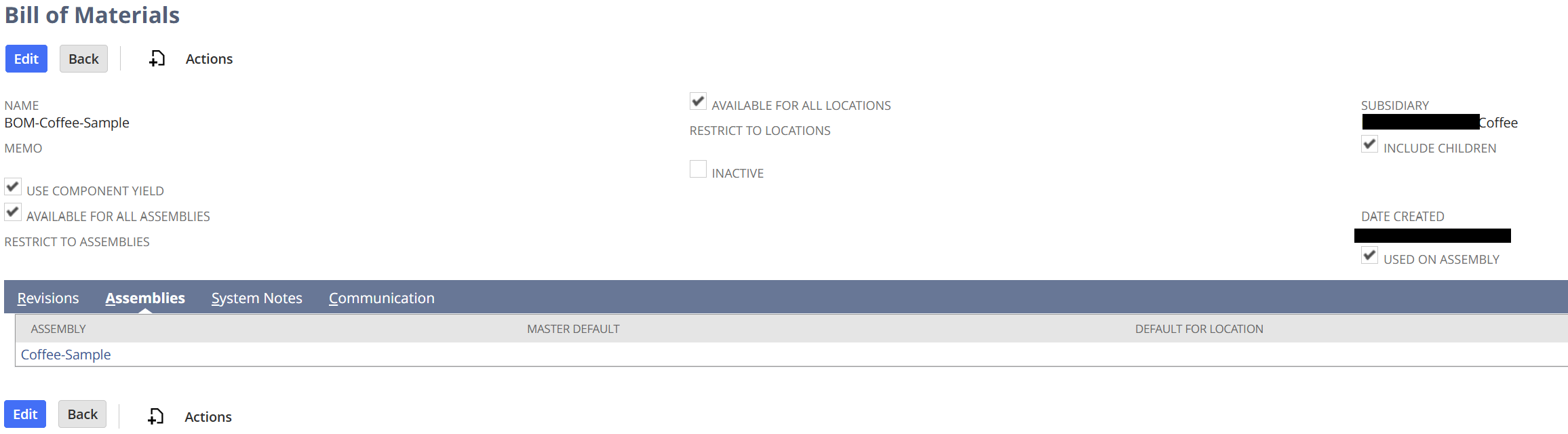

The Coffee-Sample product has a recipe attached to it via the BOM named "BOM-Coffee-Sample" that dictate 3 ingredients to assemble the finished product:

a. 7.5lb of Arabica identified as "Green Bean Arabica" in NetSuite

b. 20 6oz bags identified as "6oz Bag" in NetSuite (20oz is 7.5 lb of coffee, hence the 7.5lb in step one)

c. A brown box case identified as "Brown Box Case" in NetSuite

Make sure that you attach the BOM revision to the assembly in its' Assembly tab:

-

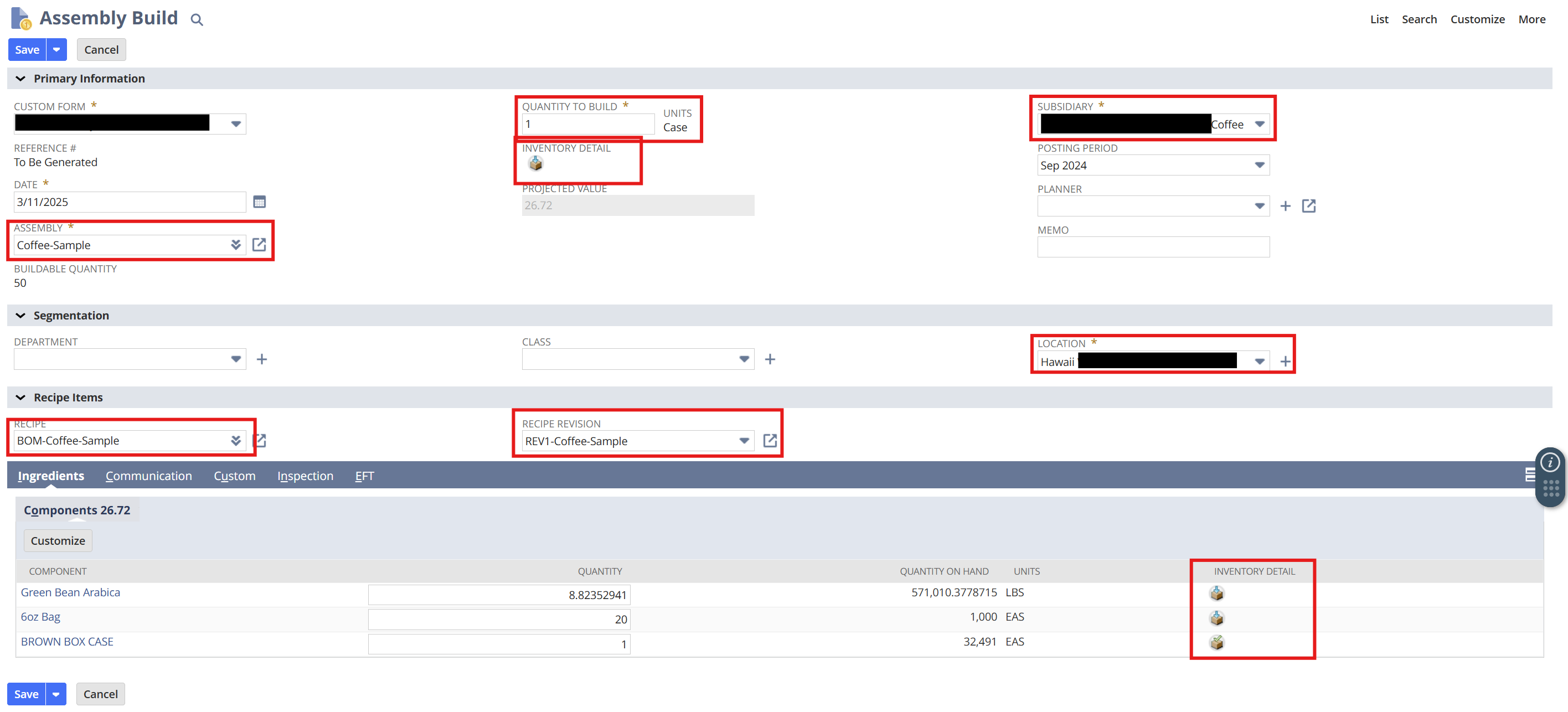

Once the BOM and its' revision are defined, we can now go to Transaction > Manufacturing > Build Assembly in NetSuite accordingly to the following fields:

-

Subsidiary - Define the subsidiary entity that you'd want to record the transaction and its' respective accounts

-

Location - Define the location of the warehouse where you'd want to replenish stock inventory of the finished good

-

Assembly - Select the finished good that you'd want to build and in this case our item that we identified in step 1

-

Recipe - Select the BOM from step 2

-

Recipe Revision - Select the Revision from step 2

-

Quantity to Build - The amount should reflect from the physical assembly of the finished from Production. Once this is input, the quantity of raw material needed to be utilize will be automatically calculated from NetSuite. Notice that for the green bean, we will need more than 7.5lb and that is because during the roasting process we are expecting a minimum yield loss of 15%

-

Inventory Detail - The inventory detail be where you define the lot of the raw component that you will draw to assemble the product

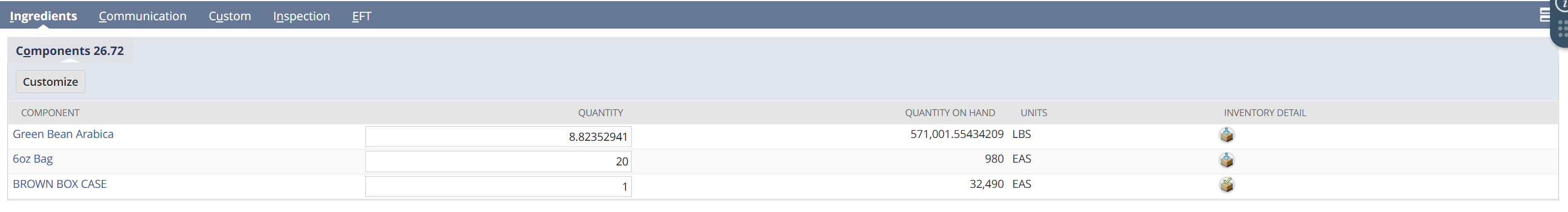

Note: If you notice the "Components: 26.72", that is how much in component cost will be when you assemble one case of the product "Coffee-Sample"

-

-

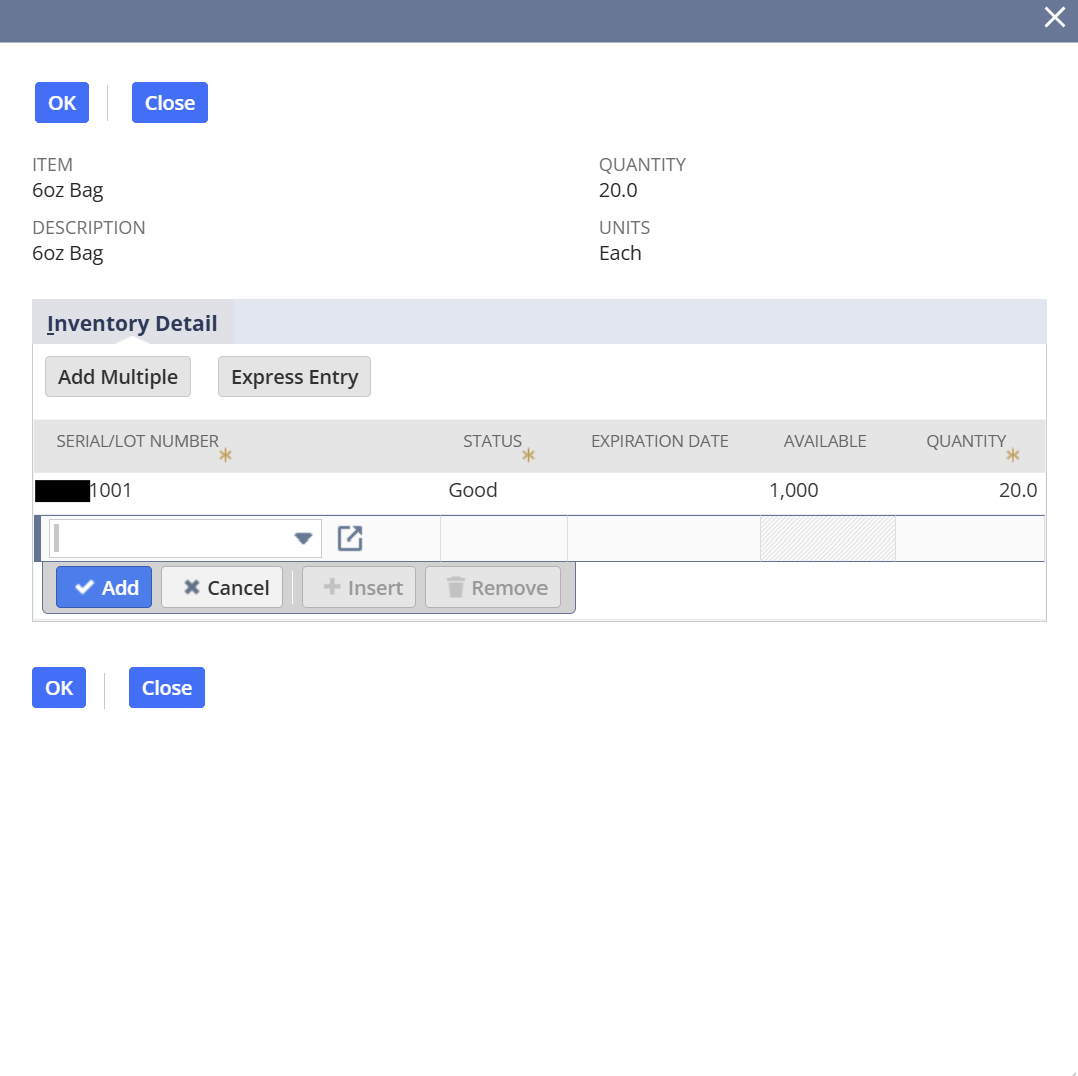

To fill the inventory detail of the raw material, for example "6oz Bag", we'll say that we'll draw 20 bags from the LOT 1001 (FIFO method of usage should be applied for simplistic strategy). The LOT 1001 currently has 1000 available

-

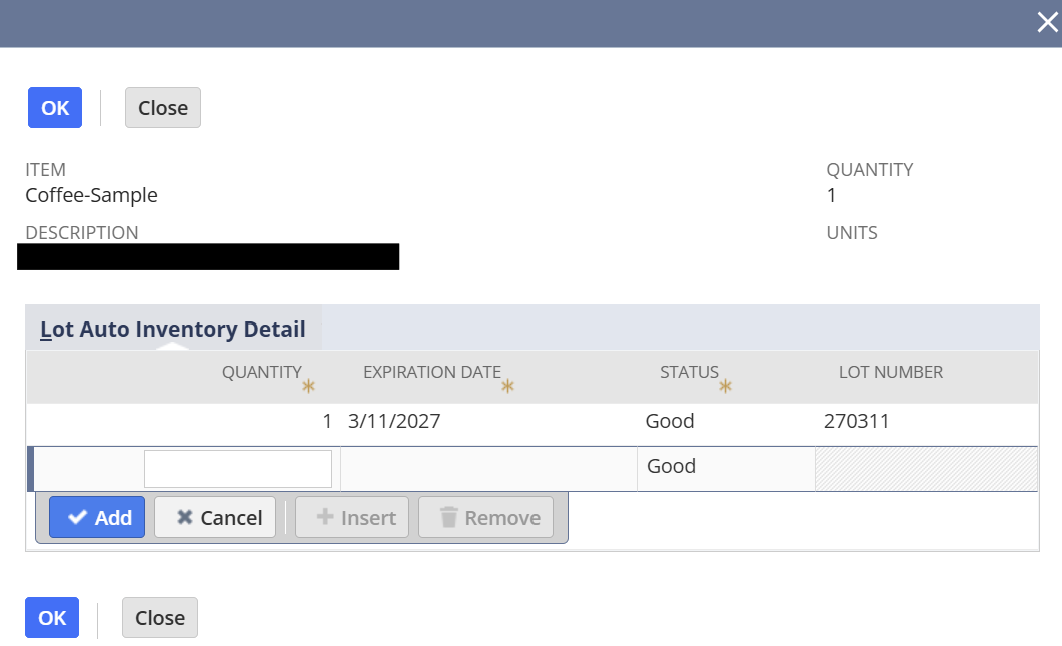

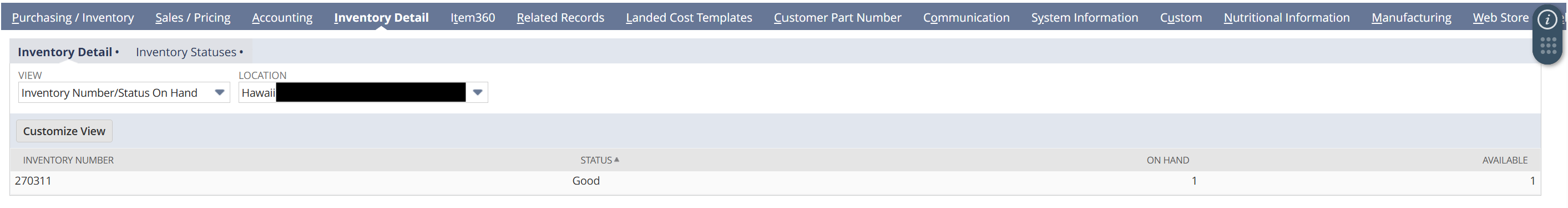

To fill out the inventory detail of the finished good, we'd define the expiration date as "3/11/2027" which should auto-populate the lot number as "270311" if you are using expiration date as the standard for lots.

-

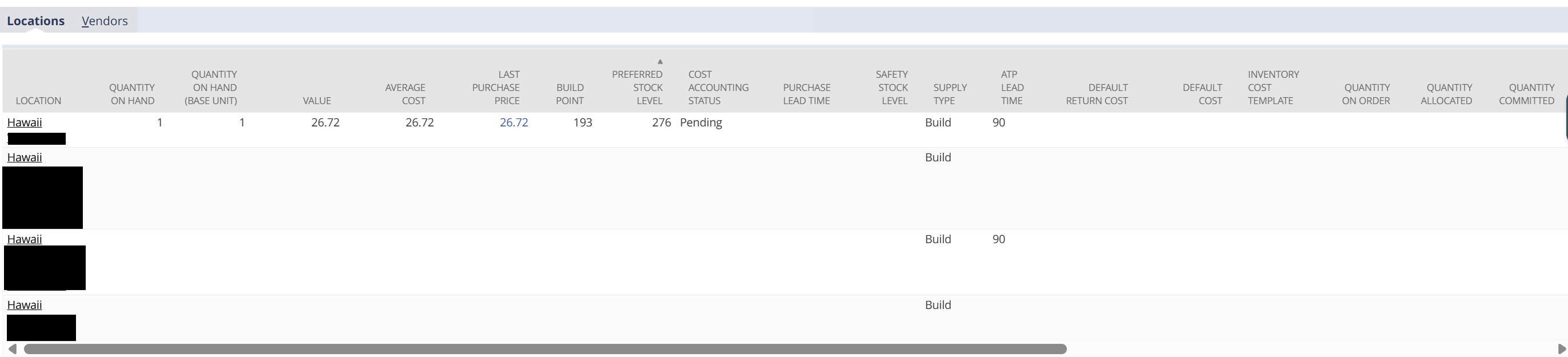

Once everything has been defined, submit the transaction. Upon transaction successful, the raw materials has been consumed and the finished good has its' stock replenished accordingly to production:

In the Item page, you can see that the quantity on hand and the current valuation of the inventory accordingly to the material used to create them:

You can verify the inventory detail and its' lot:

You can also see that the raw material quantity has decreased from consuming the raw material to make this finished good:

The obvious decrease is that we had 1000 bags on hand from LOT 1001 and its' 980 now since we used 20 bag to make one case in lot 270311